Opadry® QX

Quick+FleXible Film Coating System

Our fastest coating to date, Opadry® Quick+FleXible coating can be used with any type of coating equipment and is ready to use in just 25 minutes! Benefit from up to 40% reduction in coating and preparation time.

Process Adaptability for the Perfect Finish

• Wide Processing Latitude

• Excellent Appearance

Process Adaptability for the Perfect Finish

Opadry QX®, quick and fleXible film coating, is settingnew productivity, efficiency and appearance standards forcoated tablets. As an innovative technology breakthrough, Opadry QX greatly reduces solution preparation and coatingproduction times, operates under a broad range of processparameters in any type of coating equipment, and alwaysresults in a premium quality finish.

Gain Time with Process Efficiency

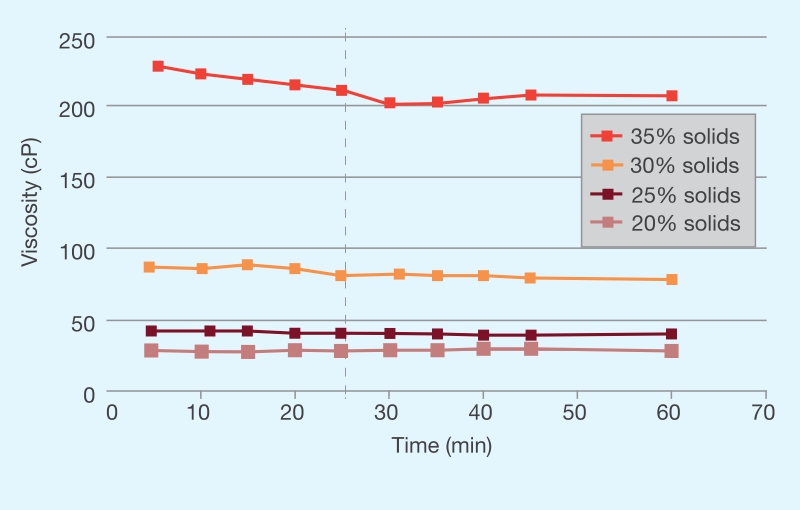

Opadry QX is a low viscosity formulation that is mixed withwater and ready for use in 25 minutes orless-cuttingpreparation time in half. Even at high solids levels up to 35%w/w, the viscosity of the formulation remains low, allowingfaster spray rates to help achieve greater productivity foreach coating run.

Opadry QX is Fully Hydrated in 25 Minutes

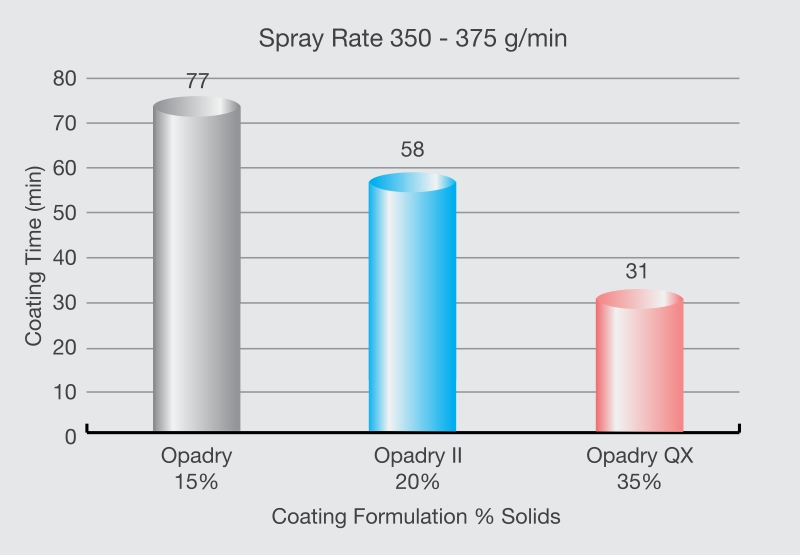

Film Coating Comparison, 48” Coating Pan

Using Opadry QX at the typical 3% weight gain, coating uniformity is achieved faster compared to alternative systems. This improved processing means tablets are exposed for far less time to the tumbling, heat and moisture associated with coating.

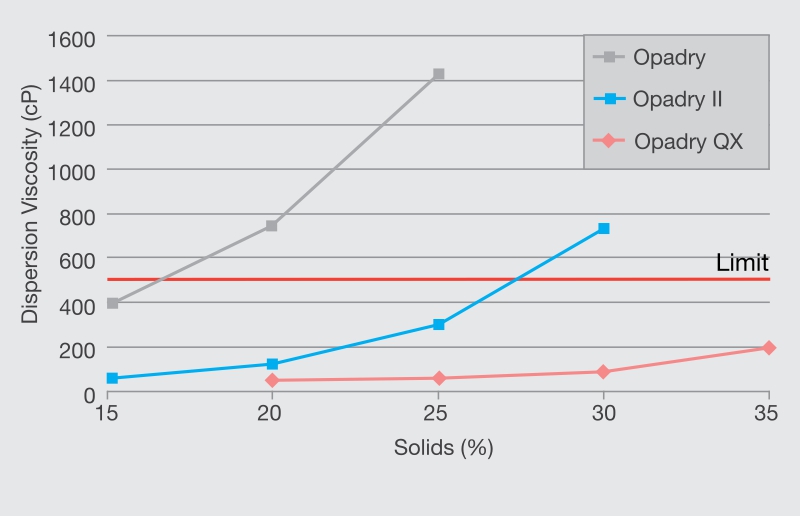

Opadry QX Viscosity Below Recommended Level

Overcome Process Challenges

Opadry QX offers unparalleled process and equipment variability without compromising the tablet finish. It successfully outperforms previous coating systems through variable bed temperatures, solids dispersion levels, plus air flow adaptability.

Broad Tablet Bed Temperatures

Opadry QX can be applied at higher bed temperatures which decreases coating times and reduces the impact of humidity. Yet the fleXibility offered of operating at low bed temperature settings also makes Opadry QX a film coating ideally suited for temperature-sensitive active pharmaceutical ingredients.

Solids Levels

The increased solids level achievable with Opadry QX means that films are applied faster, color uniformity reached earlier and all coated tablets have a uniform, defect-free finished appearance.

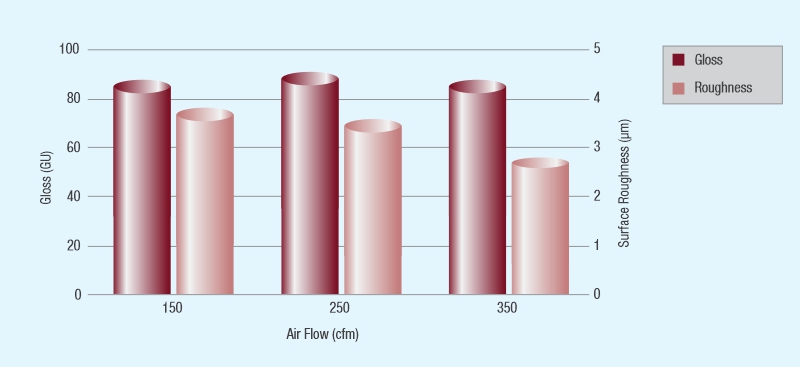

Overcome Process Challenges Air Flow

Opadry QX maintains a premium coated finish, even when used in coating equipment with limited air flow capacity. In a design of experiments (DOE) performed in a 24” fully perforated pan, air flows ranged from 150 to 350 cfm, and the resulted coated tablets were consistently glossy and smooth.

From Batch to Continuous

Opadry QX is proven to perform in all types of coating equip-ment, from solid through to fully perforated pan coaters. It has also been validated in the latest continuous and semi-contin-uous equipment representative of several manufacturers.* In each continuous coating trial conducted, Opadry QX matched the full capacity of each machine with improved coating uni-formity and a perfect finish in record time.

Regulatory

Opadry QX is proven to perform in all types of coating equip-ment, from solid through to fully perforated pan coaters. It has also been validated in the latest continuous and semi-contin-uous equipment representative of several manufacturers.* In each continuous coating trial conducted, Opadry QX matched the full capacity of each machine with improved coating uni-formity and a perfect finish in record time.

The Perfect Finish

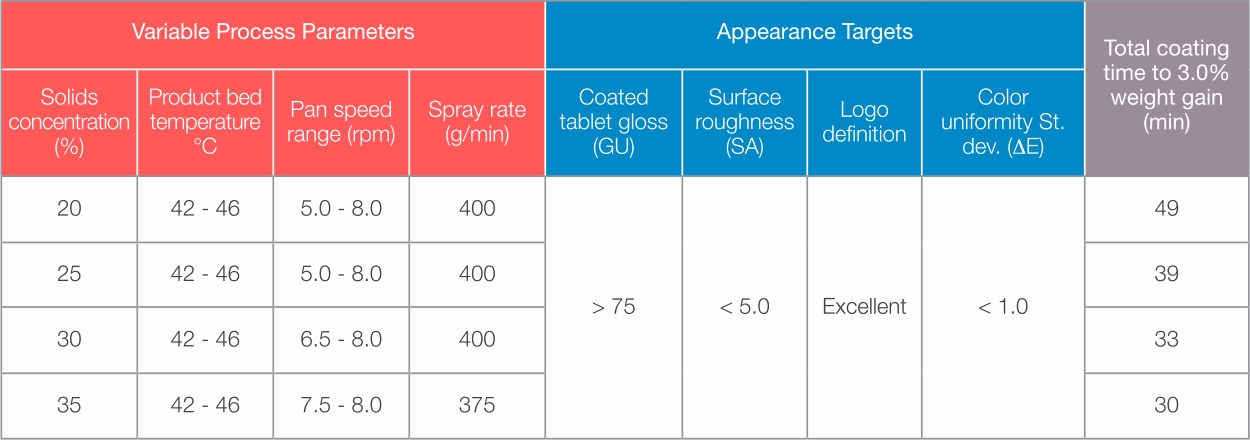

Coating with Opadry QX results in an exceptional appearance across a wide range of process variables. Demonstrated using a production scale 48” side-vented coating

pan, Opadry QX was successfully applied over a range of coating solids concentrations, variable pan speeds and spray rates.

Superior Gloss and Surface Finish

Quick and FleXible

• Easily transition drug production between manufacturing sites

• Save energy through more efficient manufacturing

Process constants: 130 kg pan load; 350 mg round standard concave placebo tablets, 1800 cfm process air flow; 3 – Schlick ABC spray guns,25 psi atomizing and pattern air pressures.

Process constants: 130 kg pan load; 350 mg round standard concave placebo tablets, 1800 cfm process air flow; 3 – Schlick ABC spray guns,25 psi atomizing and pattern air pressures.